Permaculture design process for drying and storing firewood

This is a thread that shows how I work out a design, and I am working on now and then. The start date for planning is January 20, update 22 january, 29 january.

I will make a permaculture design to dry and store firewood.

The first permaculture tool I choose to use is: needs and yield. The modest solar conditions mean that I have ruled out solar heating. I am left with electric heating and wood burning, with self-harvested wood. It is important that the wood is dry to provide power, and for that I will make a design for drying firewood. A design should accommodate multiple needs.

I investigate whether it can be combined with other needs, can food be dried there? Will there be plants in combination with the design.

When I have made a decision to move forward, I look at how it fits into the systemic design. In the spring season, firewood will be loaded, and in the winter, firewood will go into the house and into the oven. How do the logs come in, where are they stored, the wood is split. and the way into the house. In relation to daily routines Food compost is close by, mailbox

Systemic design for the yard with a wood dryer:

The yard will mainly be used for plant production, a greenhouse will be set up and benches for a nursery will be established. Firewood for own use is produced in the yard. Splitting and drying are the most important work operations.

Easiest possible firewood handling:

Logs and logs are often loaded onto the tractor trailer. I often cut the logs in the forest with a chainsaw, which is transported on a regular tractor trailer. When the logs are on the trailer, I roll them onto an electric wood splitter, split the logs and place them in the stack. Another option for splitting wood is to use an axe and a chopping block. There is also a sawing bench for manual sawing with a bow saw.

The wood dryer stack is placed where the best sun conditions are.

Behind the wood dryer, the wood is stored in bags wrapped in tarpaulin, or with corrugated iron sheets over it.

In the winter I will transport the wood into the house with a wheelbarrow or tractor. The tractor is also used for snow plowing, and it is natural to bring in wood at the same time. A bag of wood can be placed near the front door. By the front door there is a shelf for firewood that holds half a cubic meter. It acts as a buffer storage for daily wood burning.

Then I look at what is happening in the design, and for that I use the 4-element design system. I want sun and wind into my design, and water and soil out of the design. The design must be placed in a place with good sun and wind conditions.

Holmgren's permaculture principle of capturing and storing energy must be utilized here. The design must be able to capture solar heat and store it. The design must get rid of the water, avoid soil and preferably stand on stones.

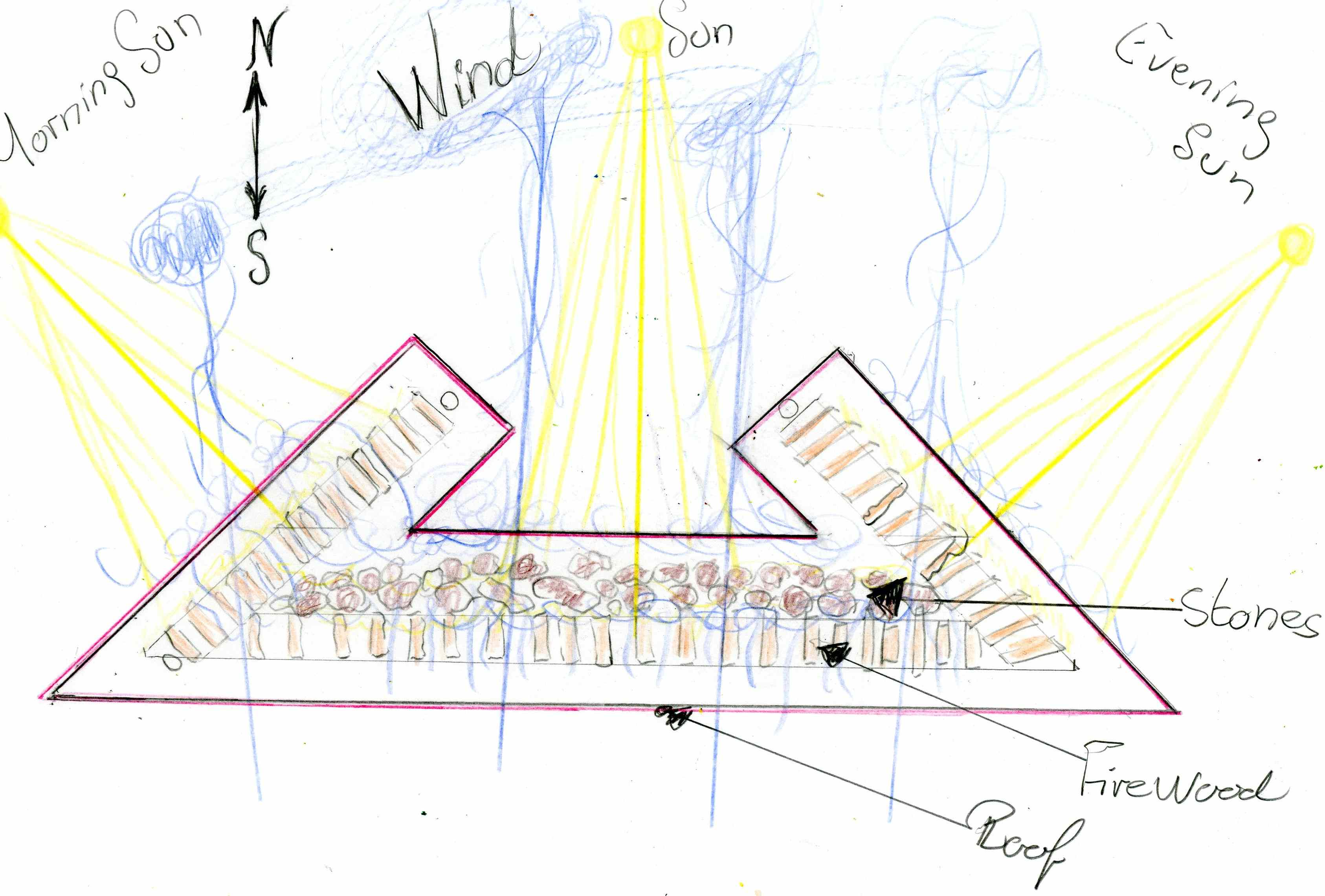

Firewood drying principle

The principle drawing of the firewood drying process above the firewood drying process is ready. To drive the water out of the firewood, heat and an air flow are required. The air must be allowed to flow through the logs. When wind meets a wall, turbulence will be created.

When the sun's rays hit the logs, they heat up. Stones are also placed in the triangle to store the heat that the sun has given off during the day. A roof must be placed over the woodshed, which can consist of corrugated iron sheets.

Principle drawing of firewood drying, drawing viewed from top to bottom. North - south is opposite to what is written in, because that sunshine comes from the south.

Principle drawing of firewood drying, drawing viewed from top to bottom. North - south is opposite to what is written in, because that sunshine comes from the south.

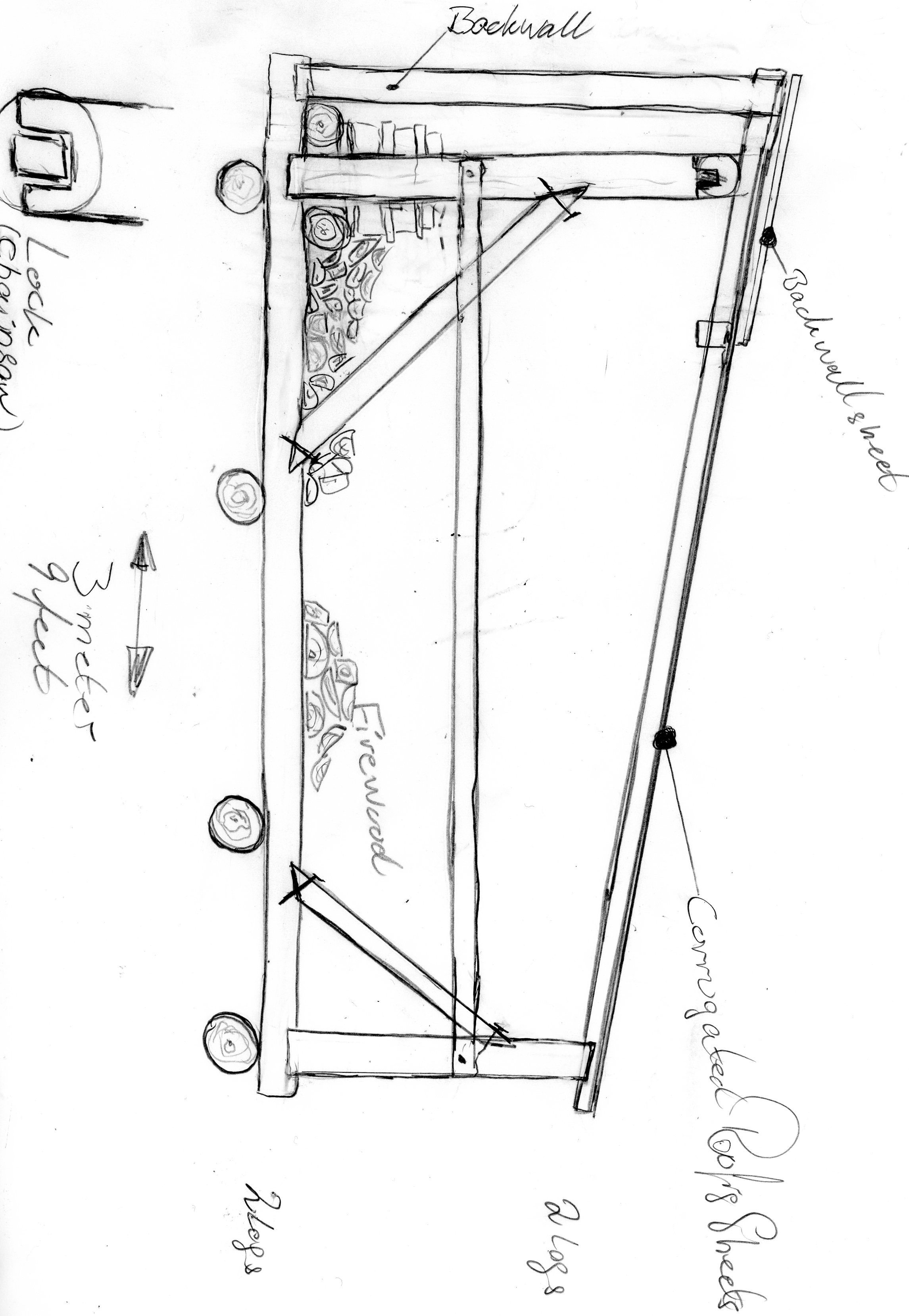

First draft of the drawing:

The drawing shows the sides of the structure, of which there are two pieces. I have not drawn the longest side, the end structure. I have drawn in locks that are easy to saw out with a chainsaw. I see that the stabilizers need to be made smaller. The stabilizers are screwed in with long wood screws.

I think the end structure will be 5 meters and will require 5*2 meters of bottom logs. The side structure will be 3 meters long and will require 3 meters*2*2. The load-bearing structure will require 2 meters*4. The bottom sleepers should be 0.5 meters, and there should be 12 of them. The structure will require 40 meters of timber. In addition, logs are required above which the corrugated iron sheets will rest, about 40 meters of that too

The drawing shows one of the two short sides. There are roof boards over the firewood. The back wall consists of logs that cross each other.

The drawing shows one of the two short sides. There are roof boards over the firewood. The back wall consists of logs that cross each other.

What is next is to prepare the site and cut the timber.

The place where the wood dryer will be located. There is a lot of rock in the ground here, and it is located a little higher in the terrain.

The place where the wood dryer will be located. There is a lot of rock in the ground here, and it is located a little higher in the terrain.